Model No.︰FEP 9494X

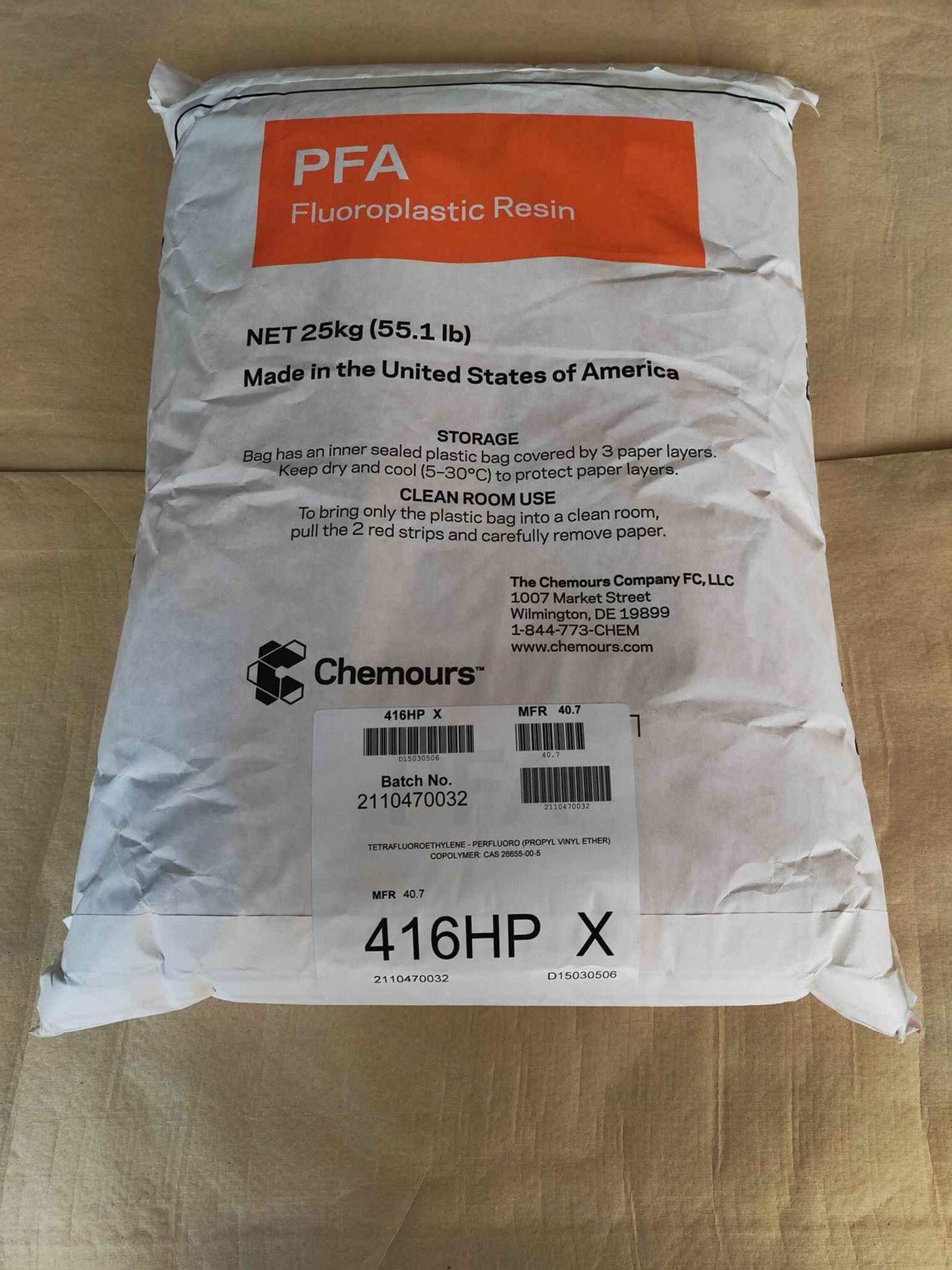

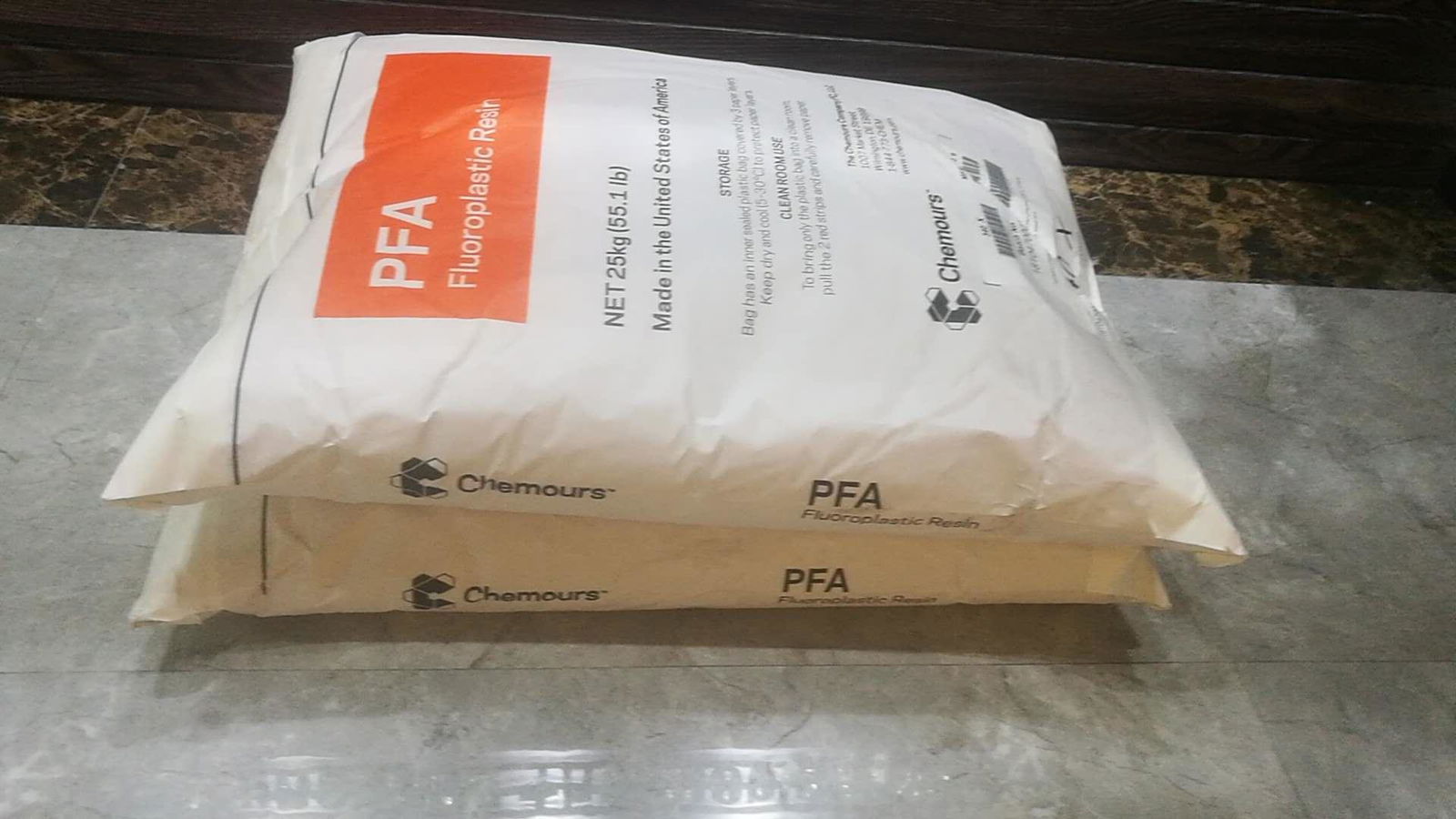

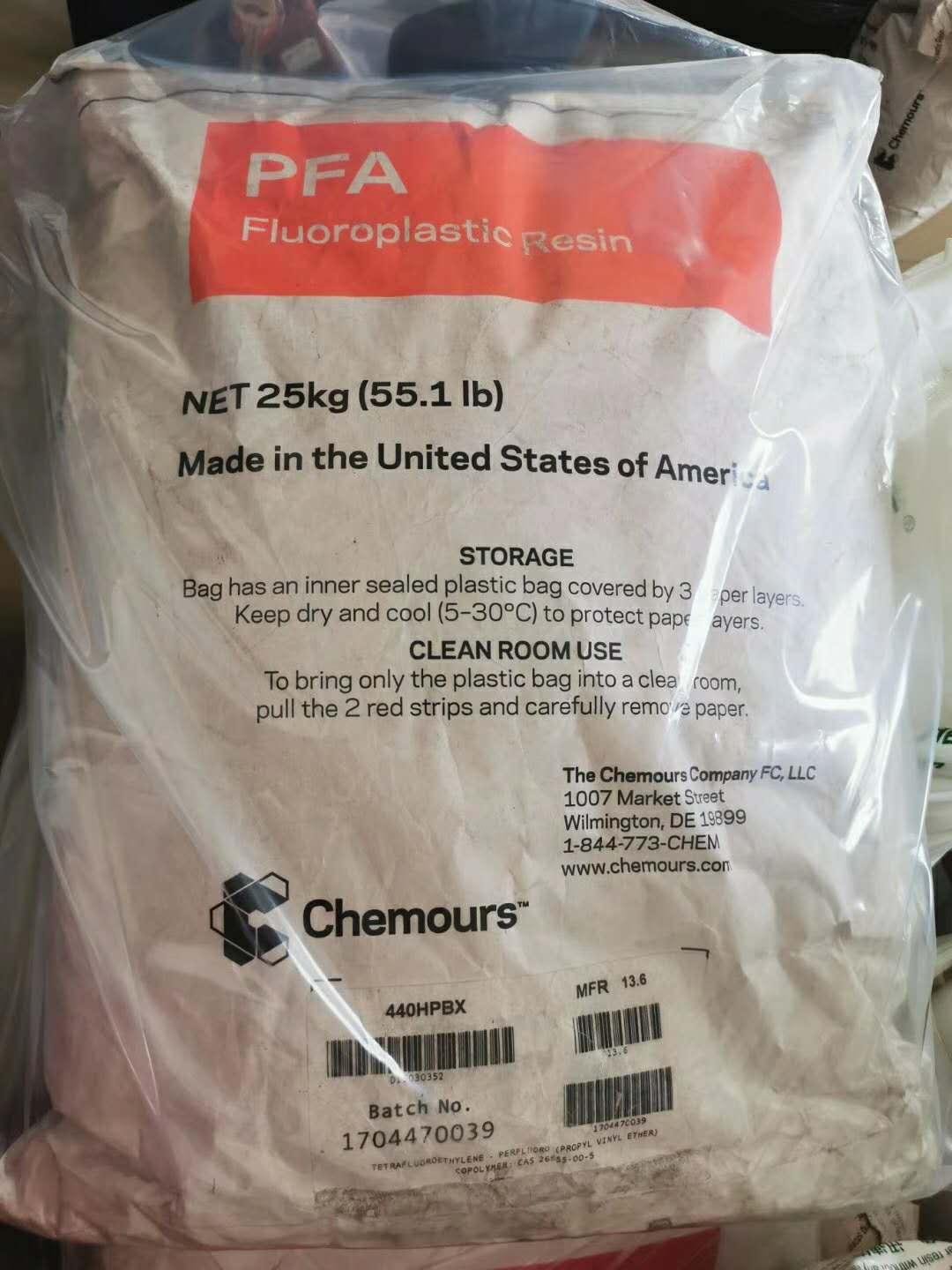

Brand Name︰PFA

Country of Origin︰United States

Unit Price︰-

Minimum Order︰25 KG

Fluoropolymer

perfluoroalkoxy (PFA) fluoroplastic grade.

tetrafluoroethylene and hexafluoropropylene (FEP)copolymer

| Type | Grade | MFR | Origin | Available |

| PFA | 340X | 13.7 | USA | 500 kg |

| PFA | 416HPX | 40.7 | USA | on request |

| PFA |

451HP-J ** 420HP-J |

2.1 35.0 |

Japan |

on request 500 kg |

| PFA | 440HPBX ** | 13.6 | USA | on request |

**Notes: Our inventory list changes every month, Marked **,This is a spot buy one time deal & not repeatable…we got this from a molder who had excess inventory. More order and datasheet/msds and other certificate and packaging pics,Please send e-mail to : x.g.chiang@gmail.com

Payment Terms︰ T/T

Packing︰ 25KG

Lead Time︰ 5 DAYS